This NC24 was an impulse buy after seeing it advertised locally. It’s a 1988 Honda VFR400 NC24 RJ-III model which had arrived in the UK during 1994 via the grey import specialist BAT Motorcycles. Since arriving in the UK its had 9 owners and was in poor condition with obvious signs of accident damage.

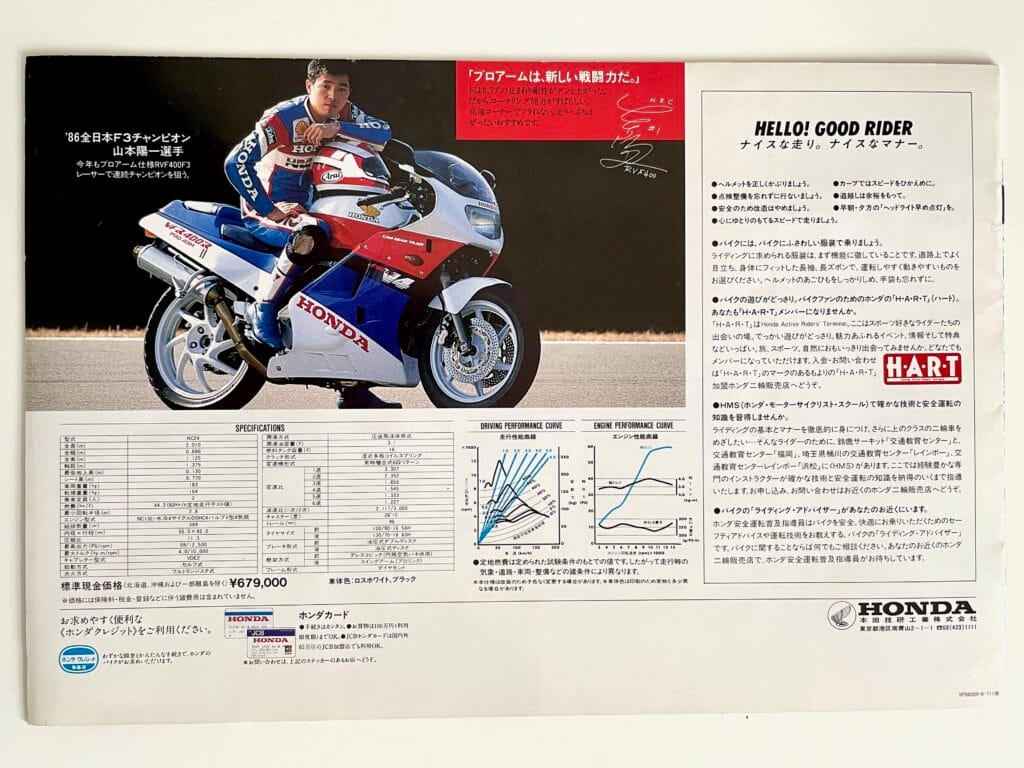

Building on the foundation of its predecessor, the NC21, Honda introduced the VFR400 NC24 with some significant upgrades. Among the most notable was the new high-level exhaust and, for the first time on a Honda production bike, the Elf-designed PRO-ARM single-sided swingarm – an innovative feature that set it apart.

Produced exclusively for the Japanese domestic market in 1987 and 1988, the NC24 was Honda’s response to strict licensing regulations at that time. Despite its small displacement, the NC24 packed a punch with its water-cooled, 16-valve V4 engine, complete with gear-driven cams, delivering an impressive 59bhp.

As a Japanese domestic model, printed material in English is scarce, but there’s a lot of information available online. A great resource is the 400Greybike forum which was quite active at the time and contains a wealth of information. However their Facebook page, 400greybike is now much more popular. Another Facebook group is the Honda VFR400 NC24 &NC21 Community.

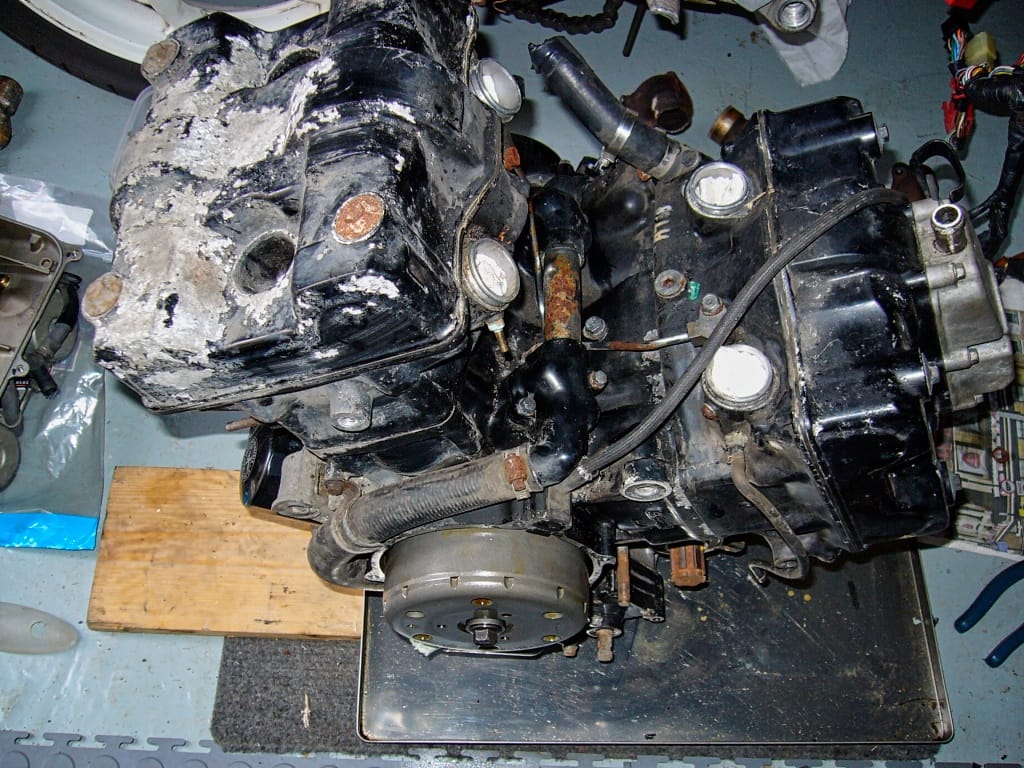

Apart from a bent subframe, clip on and badly damaged fairing this Honda VFR400 NC24 looked complete and straight. The exhaust was very badly corroded and fell apart on inspection. I’d wrongly assumed that if it was too bad to weld I could get a used or new replacement. I hadn’t done my homework. Firstly, it’s a discontinued part. Decent second hand collector boxes are almost impossible to find. They also command a premium. Secondly, it’s not possible to remove the collector box and exhaust pipes without removing the engine from the frame.

The electrics were in good condition except for the HT leads and plug caps which were past their best. The correct caps were hard to find. Eventually a new set was sourced from NC30/35 specialist Rick Oliver who can also supply some NC24 parts. The entire wiring loom was checked for damage. All connections were carefully cleaned as some were showing slight signs of corrosion. The stock regulator has a poor reputation for reliability and R6 regulators seem to be a popular alternative. Fitting details are well covered in the 400Greybike forum. The regulator was a tight fit and I had to file two channels across the fins. This made room for the ht leads, which are routed below it.

The polymer bush on the fork anti dive mechanism had worn. I was unable to source a replacement. It was another discontinued NC24 part. The hardened steel piston collar (also discontinued) which fits inside the bush had cracked. This caused it to be slightly wider where the snap ring fits. I’ve also seen this in two other collars which were among some used spares I bought. Searching online I found plain bronze bushes (8x11x8mm) at £7 for a pack of 5. It was an easy job to press out the old worn plastic bush and fit the bronze bush.

For anyone interested in metallurgy, chemical analysis revealed that the collar had been produced from a free cutting steel. It had a nominal composition of 0.42% carbon, 0.23% sulphur and 1.0% manganese. The surface hardness was 55HRC. High machining rates are achieved during production by using free cutting steels. However this comes at the expense of ductility and toughness. The high hardness undoubtedly compounds this issue. I’ve since had some replacement piston collars machined from Uddeholm THG 2000. This is a high strength special steel, prehardened and tempered to 40HRC. I’d expect this to be significantly more crack resistant than the free cutting steel originals. Please note that this modification is the way I carried out the work. It should not be understood as the official or necessarily the correct way.

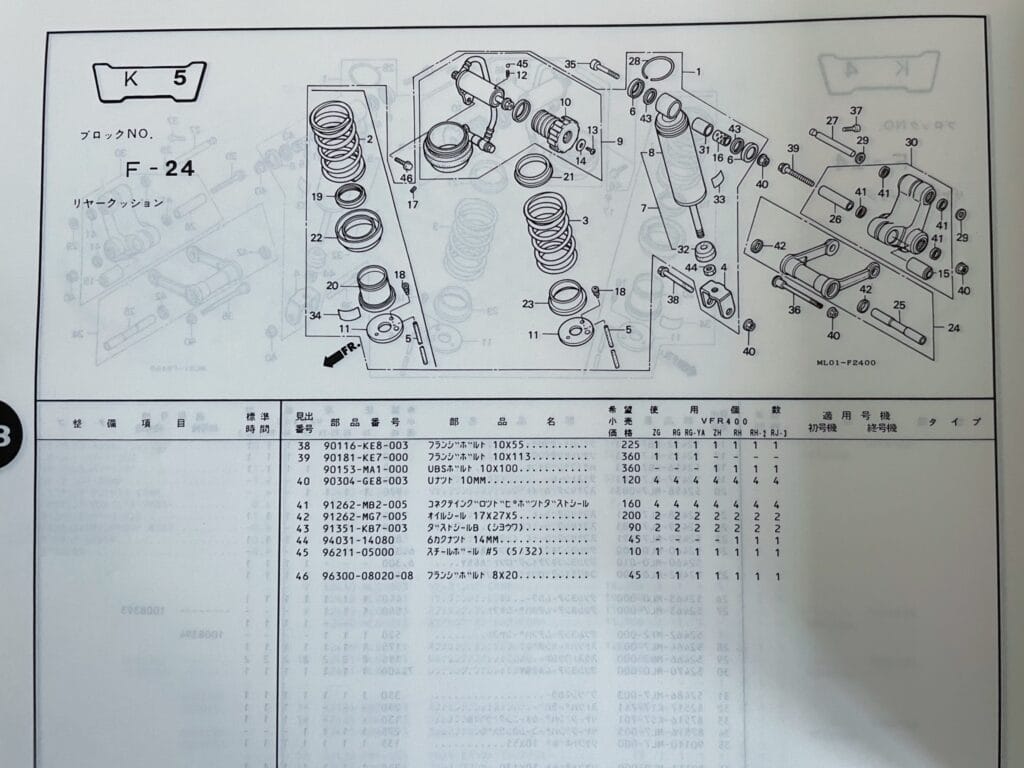

Fork servicing can be tricky if both legs are dismantled together and the parts mixed. Some internals of each leg are different and unfortunately there isn’t an English manual. However, they are very easy to work on. It only needs a few minutes study of the online parts microfiche or the Japanese parts and workshop manuals. Firstly the stanchions are different lengths and the shortest fits in the antidive leg. The oil dampers are different too but are easy to identify from the microfiche. The source of most confusion seems to be the alloy oil lock piece. It should fit on the antidive side with its flange down. Again this is clearly shown in all the microfiche and Japanese manuals. Many seem to assume this is a printing error and install it the other way. The fork springs are installed with the tightly wound section uppermost.

The NC24 model features 37mm diameter front forks, while the later VFR400 NC30 is equipped with larger 41mm forks. This difference in size is crucial when ordering replacement fork seals and bushes. Always double-check the dimensions before making a purchase to avoid receiving the incorrect parts. I’ve encountered this issue personally on two occasions, as some suppliers were unaware of the variations between these models.

At first I found installing the carbs to be a real challenge. I’ve since found the best way is to use a light smear of red rubber grease and secure the front rubbers to the head. Next place the rear rubbers partially on the head at an angle. Push the front carbs into place and as they slide home push the rear carbs into place. There’s definitely a knack to it and it works just the same on the VFR750 too.

Initially, the panels and a Skidmarx fairing were painted by Dream Team in the Lucky Strike colours. Over a lengthy period of time I managed to collect a full set of original plastics and a tank. These are becoming increasingly hard to find in decent condition. I had to bid for a couple of panels on the Japanese Yahoo auction site to complete the set. Paintwork was carried out in original colours by Hull based Rapier Paintwork.

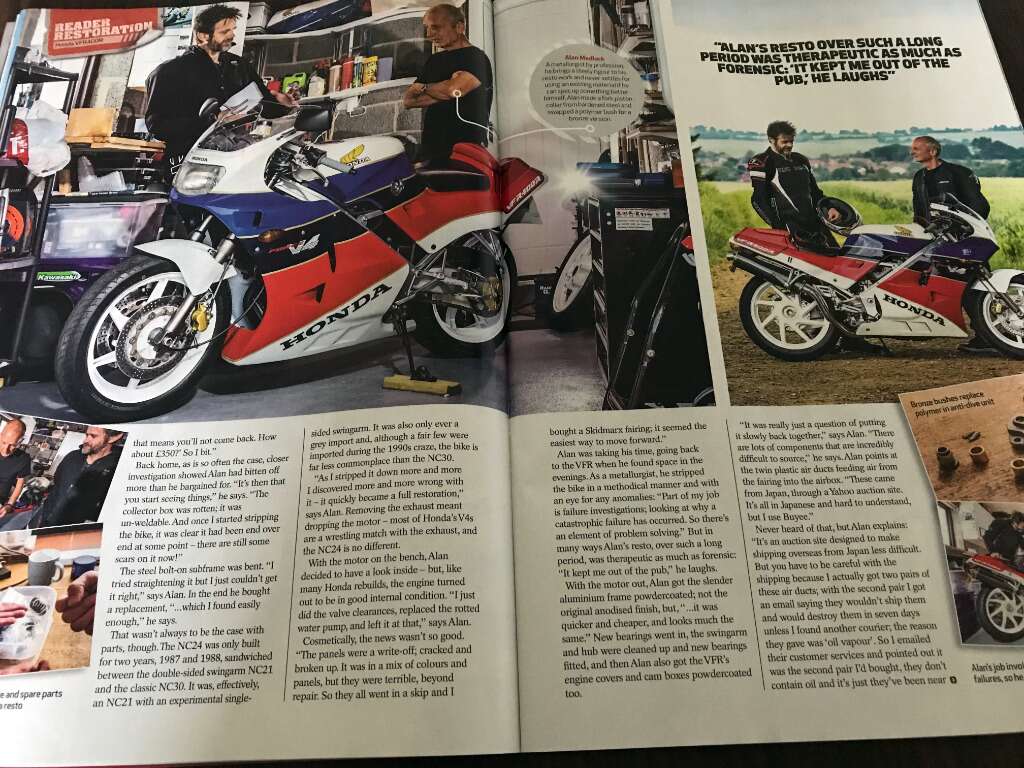

The build was featured in the August 2018 issue of Practical Sportsbike. During the photoshoot, motorcycle journalist Simon Hargreaves experienced some unnerving slides on the bike whilst cornering. NC24 forks are known to be soft and I’d sort of accepted it. I’d fitted a Hagon rear shock during the build to replace the original worn out unit. I’m currently refurbishing a standard rear shock to get the bike as near factory as possible.

The forks were standard, just as they left the factory. After a short discussion we felt that whilst it was ok for me, it was too soft for Simon. We decided that the forks would benefit from a spring upgrade. Other NC24 owners have fitted Maxton springs with good results and I’d previously spoken with Maxton. The following week I ordered a custom set of springs and spacers based on my weight. Turnaround time was quick. The spacers were neatly machined aluminium versions. They replaced the cheap tubular sheet metal efforts fitted by Honda. Although I expected an improvement in handling, the transformation particularly under braking, was huge.

Interestingly, the popular 90s magazine, Grey Bike, generally praised the handling during its road test of a 1987 Honda VFR400 NC24. Possibly a reflection of suspension technology at that time.

Decent suspension helps here and despite the relatively firm setup of the bike I rode, the suspension remained compliant enough to soak up bumps and road irregularities… The front end makes do with a set of conventional teles adjustable by means of air valves, and these do a great job keeping the front end under control, especially when pulling hard on the pair of two pot Nissin Calipers…

Grey Bike magazine Summer 1995

Parts availability.

Some new and aftermarket parts can still be obtained from cmsnl, Wemoto and David Silver Spares. Additionally Rick Oliver, although a Honda NC30/35 specialist, can also supply some parts. Many NC24s have ended their lives at the breakers and there is a large used spares market. However certain items are becoming increasingly rare in good condition and you can expect to pay a premium! These include:

Petrol Tanks

Collector boxes

Petrol taps with filters

Gear levers

Air intake snouts and frame retainers

Genuine fairing panels

Printed Resources.

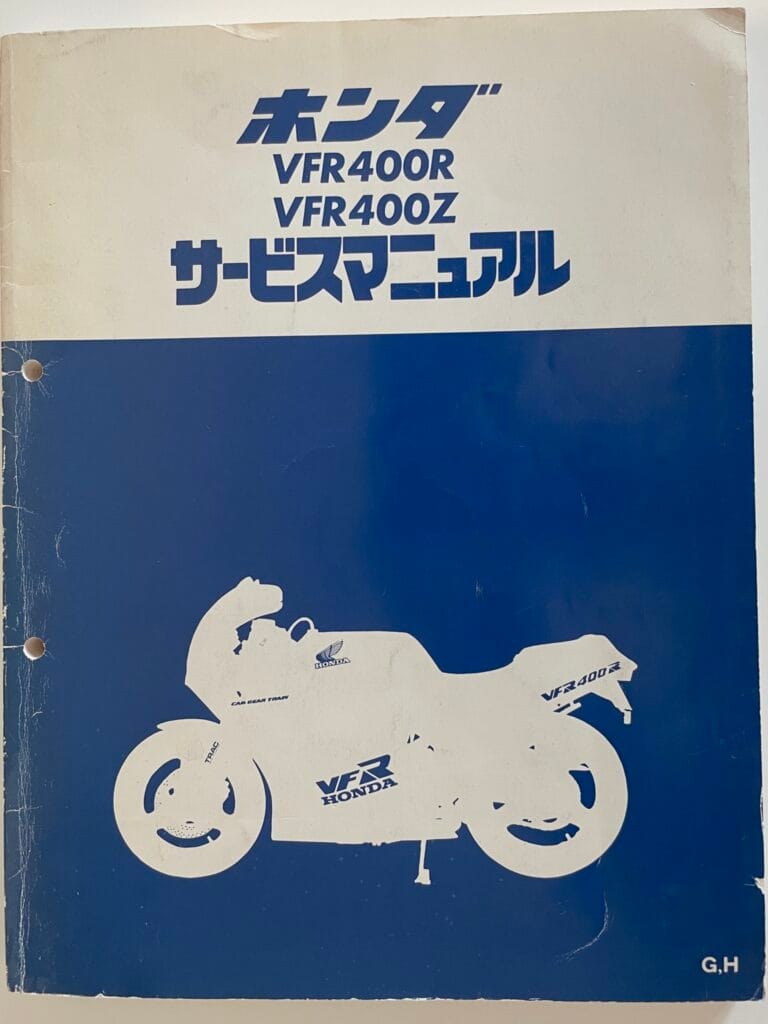

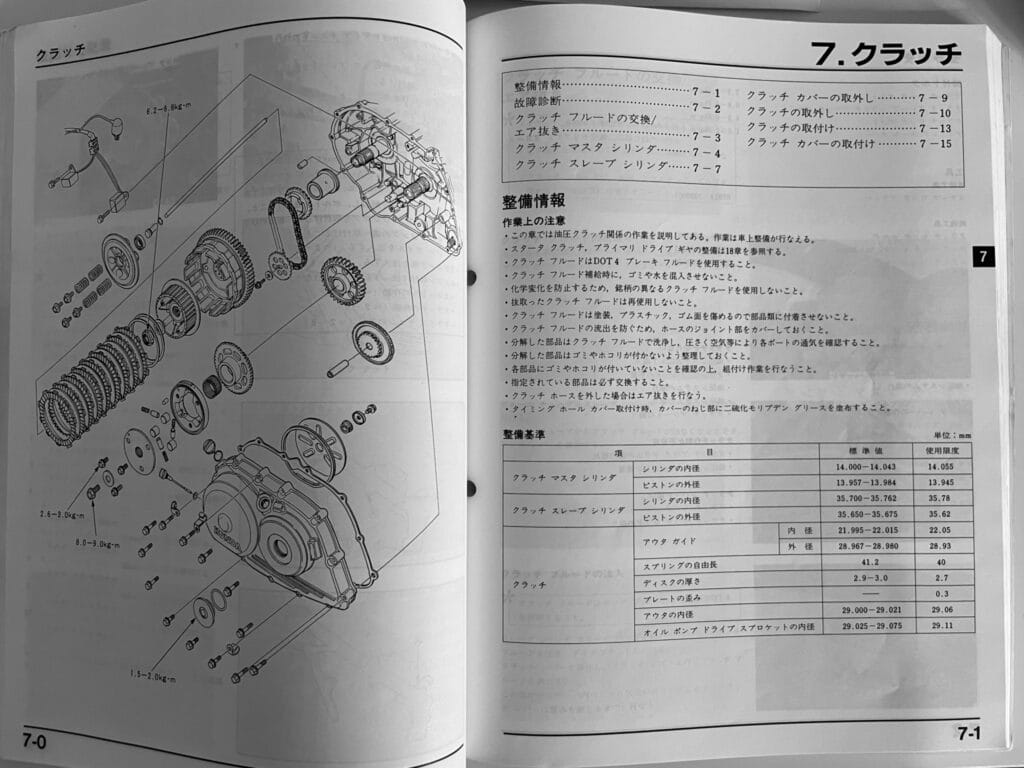

As I mentioned earlier there’s very little printed material in English for the NC24. There are a few pages of NC24 specifications and torque settings appended in the Haynes Service and Repair Manual for the later, and very different, NC30 and NC35 models.

The Japanese Workshop Manual, Part List book and Riders Manual are all usually available on the Japanese Yahoo auction site. I used Buyee Japanese proxy service. The site is also great for hard to find parts, but make sure you read the excluded parts list for shipping. Alternatively some files are available for download from 400Greybike forum and the Honda VFR400 NC24 & NC21 Community Facebook page.

Comments